Recently, the research team led by Prof. Li Xin from the Institute of Electrical Engineering (IEE), Chinese Academy of Sciences proposed a novel approach of coupling concentrated solar energy with high-temperature electrolysis for hydrogen production and successfully developed a prototype.

Hydrogen energy occupies a crucial position within the realm of non-fossil energies. Among the diverse array of hydrogen production techniques, high-temperature electrolysis stands out with a relatively high efficiency in generating hydrogen. When integrated with solar energy, it enables the achievement of clean hydrogen production and holds the promise of emerging as a predominant hydrogen production approach. Presently, the coupling methods between solar energy and high-temperature electrolysis are mostly indirect coupling. Solar energy is initially utilized to generate high-temperature steam, which is subsequently introduced into a solid oxide electrolysis cell (SOEC) to trigger electrochemical reactions for the production of hydrogen. However, this approach suffers from drawbacks such as low equipment integration and significant heat transfer losses.

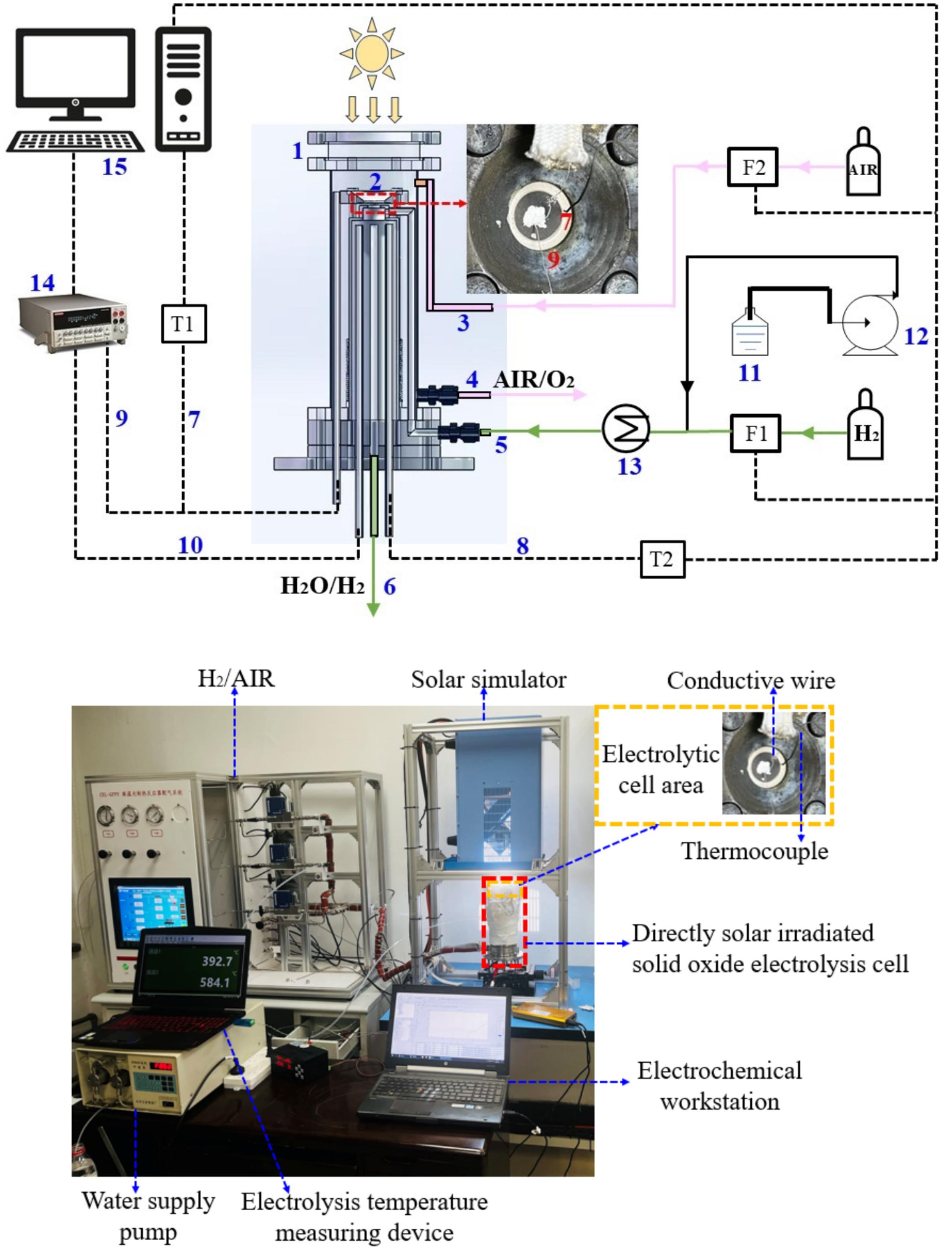

The research team innovatively proposed a novel concept of a directly solar irradiated solid oxide electrolysis cell. By irradiating concentrated solar energy directly into the porous electrode, they successfully built a prototype. They also revealed, for the first time, how concentrated solar energy affects the concentration polarization of the electrolysis cell. Compared to an electrically heated SOEC of the same size, this technology speeds up the SOEC's startup nearly 12-fold and cuts the total energy consumption (including thermal energy) by up to 76%.

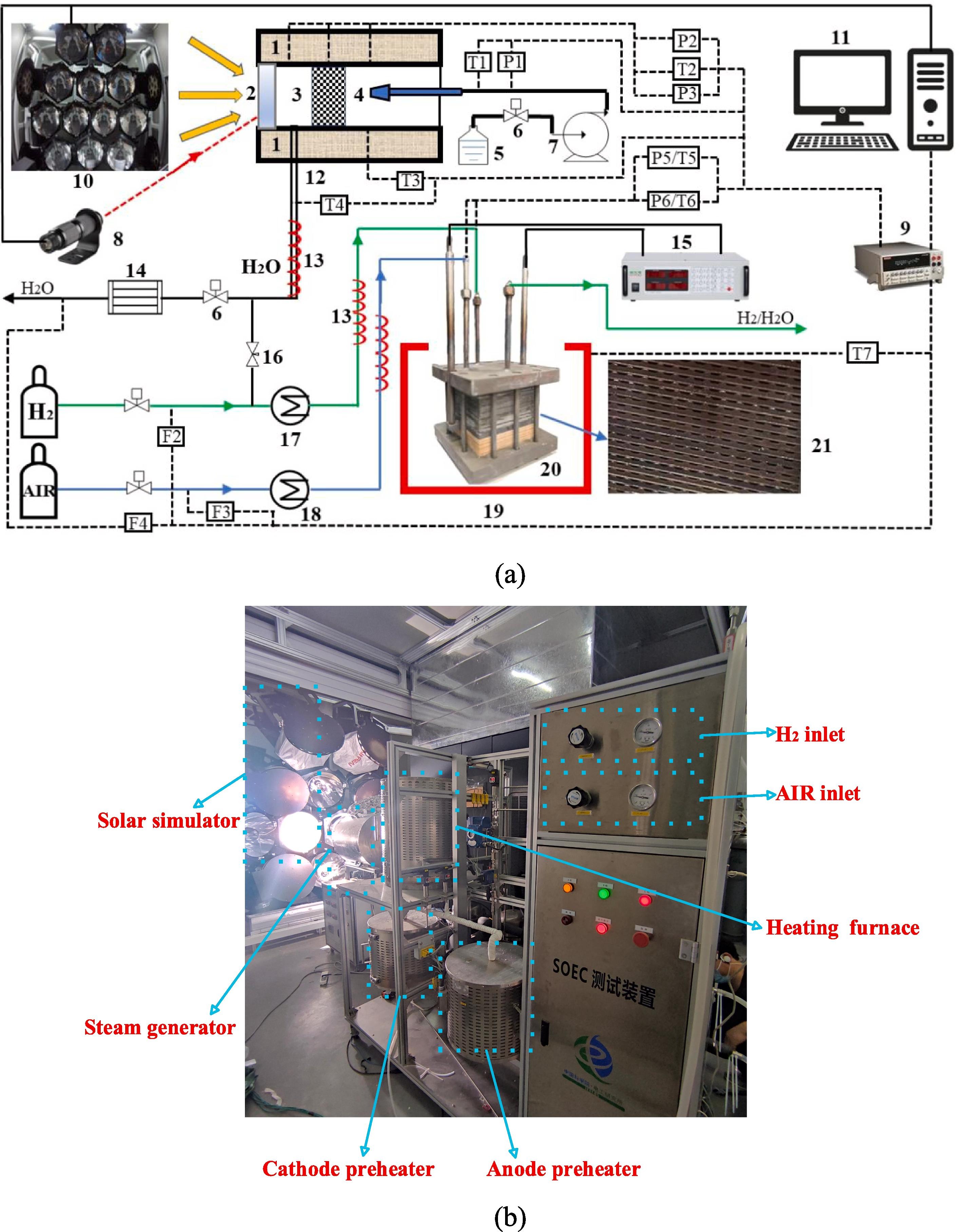

In addition, the team developed a novel solar steam generator operating in the indirect coupling mode. This generator augments its heat transfer capabilities by incorporating porous ceramic material within and utilizing the spray cooling technique. Through these enhancements, they succeeded in elevating the outlet temperature of the steam generator to 877 oC, achieving a thermal efficiency of up to 60.92%. Then the team constructed a pioneering 5 kW hybrid system that couples the solar steam generator with SOEC stacks. The peak hydrogen production efficiency of the system reaches 95.2 %(based on the lower heating value of hydrogen), and the maximum steam conversion ratio approaches 92%, giving a cumulative hydrogen production yield of 5,840 NL in 6.3 h. In contrast to the traditional electrolysis systems that rely on electricity or fossil fuels to produce steam, the hybrid system is capable of achieving a 30% reduction in electricity consumption.

These research works were supported by the National Natural Science Foundation of China, the Beijing Natural Science Foundation, and the IEE fund. The relevant research results were published in the journals "Chemical Engineering Journal" and "Energy Conversion and Management".

The paper link 1: https://doi.org/10.1016/j.cej.2024.156255

The paper link 2: https://doi.org/10.1016/j.enconman.2023.118023

Fig. 1. Prototype of directly solar irradiated solid oxide electrolysis cell

Fig. 2. 5 kW hybrid system that couples the solar steam generator with SOEC stacks

Fig. 3. Comparison of electricity consumption between the hybrid system and traditional high-temperature electrolysis system