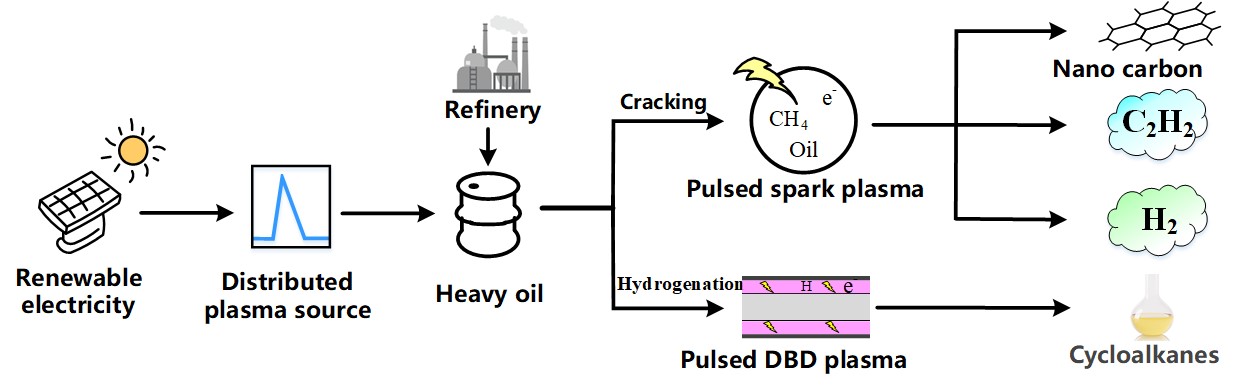

The heavier trend of crude oil in the world is serious. It is a challenging task to make full use of heavy oil efficiently and cleanly. Plasma technology is a potential approach to tackle this problem without catalysts, high-temperature and high-pressure conditions during the reaction. It also has the advantages of short process flow, low carbon emissions and wide material adaptability. However, this technology is complicated due to the inert nature of the heavy oil.

A research team led by Prof. SHAO Tao from the Institute of Electrical Engineering of the Chinese Academy of Sciences combined with Sinopec Research Institute of Petroleum Processing Co. Ltd has explored the conversion laws and reaction mechanisms of plasma-enabled heavy oil conversion using different types of pulsed discharge plasma.

The study was published in Chemical Engineering Journal respectively on April and June respectively.

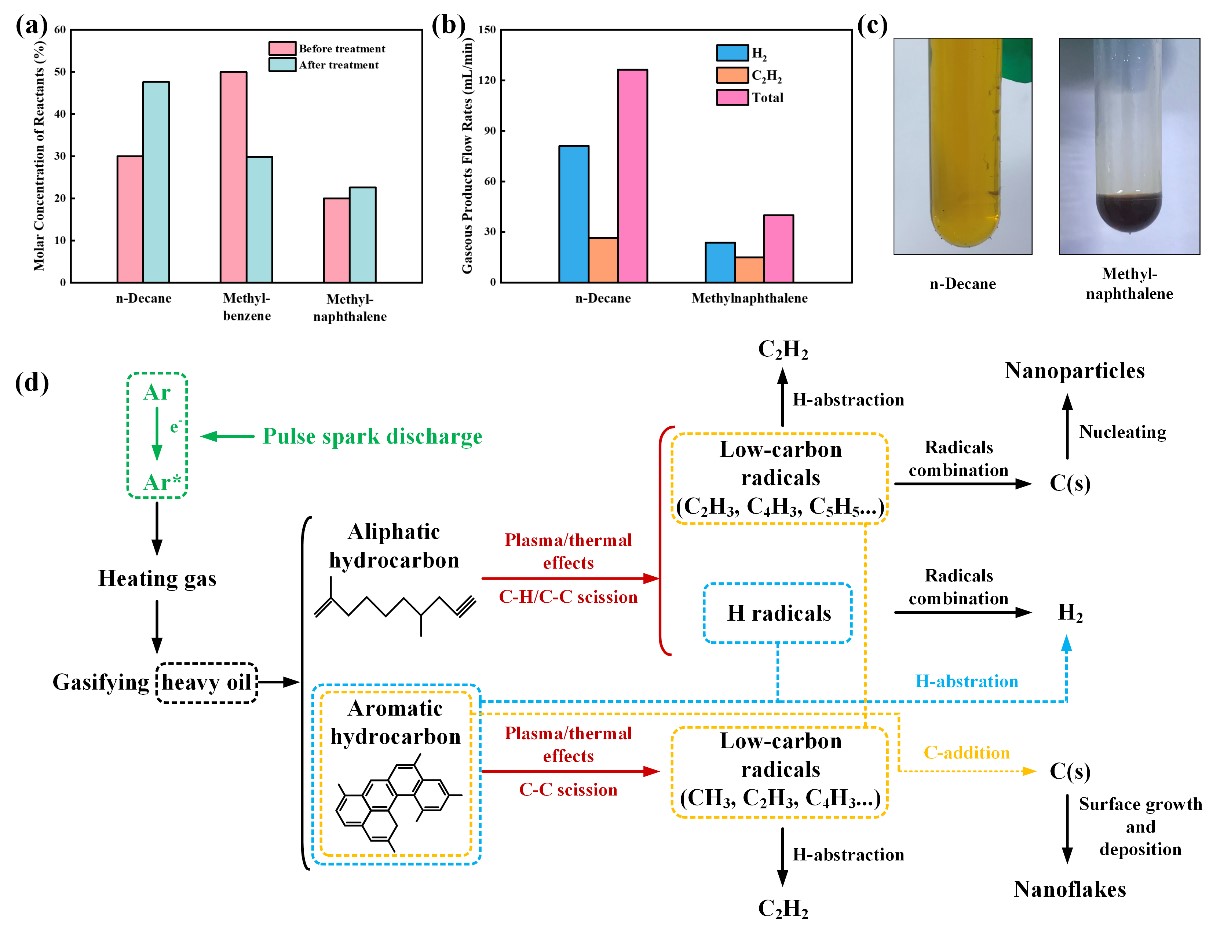

In this work, the rapid heating and cooling mechanism of the pulsed spark plasma have been revealed, and one-step cracking of heavy oil to acetylene, hydrogen and nano-carbon materials has also been achieve with a conversion rate of 50.4%, acetylene yield and energy consumption of 19.7% and 55.4 kWh/m3.

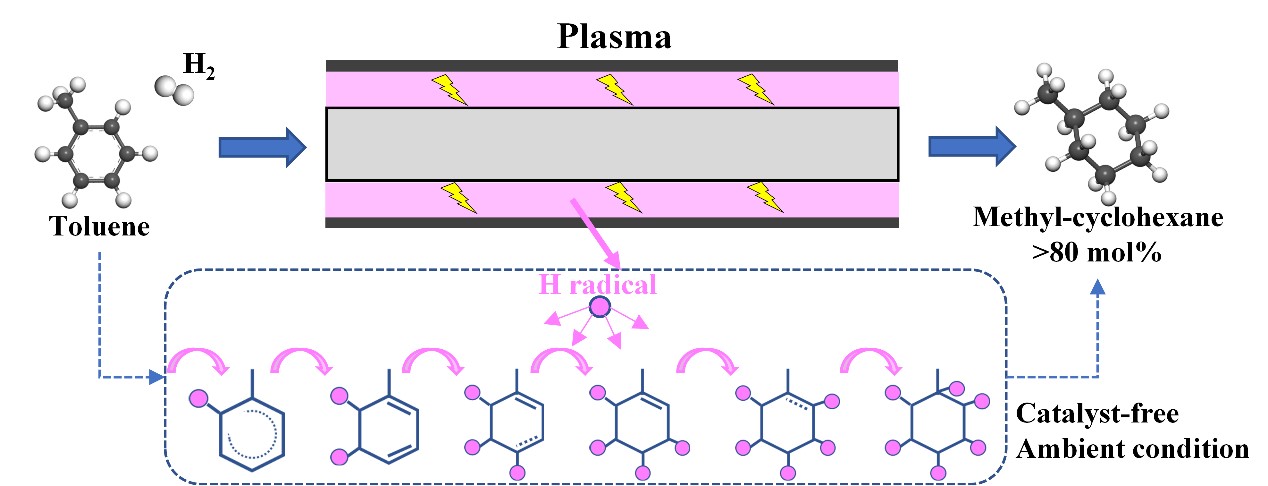

In addition, the researchers realized non-catalytic aromatics hydrogenation to cycloalkanes at mild conditions using pulsed dielectric barrier discharge plasma, which has broken the limitation of catalysts and harsh conditions in conventional heavy oil processing.

This study provides an essential guidance for plasma-enabled heavy oil processing research in the future.

Acetylene, hydrogen, and carbon materials prepared by pulsed spark plasma

Cycloalkanes prepared by pulsed dielectric barrier discharge (DBD) plasma

Application scenario of plasma-enabled heavy oil processing

Refenrence:

1.One-step high-value conversion of heavy oil into H2, C2H2 and carbon nanomaterials by non-thermal plasma

2.Catalyst-free toluene hydrogenation to methyl-cyclohexane by pulsed DBD plasma under ambient conditions

Contact:

Dr. SUN Hao

Institute of Electrical and Engineering of the Chinese Academy of Sciences

E-mail: sunhao@mail.iee.ac.cn