Recently, Prof. MA Yanwei’s group from Institute of Electrical Engineering, Chinese Academy of Sciences (CAS) has made significant progress toward scalable production of graphene and its application into high-performance supercapacitors. Their protocol is based on the self-propagating high-temperature synthesis (SHS) technique with CO2 as carbon source, and successfully realizes the efficient, green, low-cost production of graphene with high conductivity and high surface area. The related work has been published on Advanced Materials (2017, 1604690), and has applied Chinese patent and patent of Patent Cooperation Treaty (PCT).

Graphene is a novel material receiving global investigation, but the scalable manufacturing of high quality graphene products on an industrial-scale is still considered a great challenge. Currently, protocols for graphene mass-production heavily rely on the exfoliation of expanded graphite and the reduction of graphite oxide. However, the former method usually produces stacked graphite flakes with low specific surface area, while the latter generally introduces numerous oxygen groups and defects, leading to low electrical conductivity. Therefore, the practical application of graphene is now severely hampered.

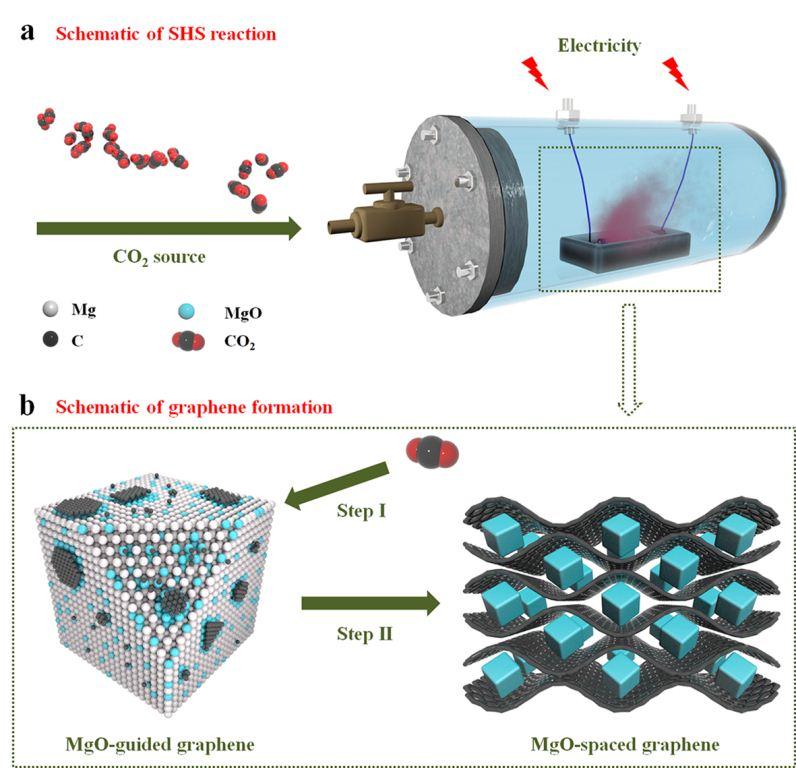

Aiming to solve such problems, Prof. MA Yanwei’s group successfully fabricated graphene materials with ample porous structure through controllable SHS process, which utilizes carbon dioxide as raw material, magnesium as reducing agent and nano magnesium oxide as template. The graphene products show excellent overall properties, including high electrical conductivity of 13000 S/m and specific surface area of 709 m2/g. In ionic liquid electrolytes, the graphene exhibits a high specific capacitance of 244 F/g as well as superior energy density of 136 Wh/kg and power density of 1000 kW/kg. The capacitance retention is higher than 90% after 1 million cycles. The SHS protocol for graphene production is time-efficient, environment-friendly, low-cost and readily applicable in industrial occasions, which is envisages as a vigorous promotion of graphene in energy-storage fields like supercapacitors.

This work is collaborated with Prof. LI Jiangtao’s group from Technical Institute of Physics and Chemistry CAS and Prof. LI Jianqi’s group from Institute of Physics CAS. This work is financially supported by the National Natural Science Foundation of China.

a) A schematic illustration of the reaction chamber and the SHS process. b) The dual role of MgO in forming few-layered graphene (left: guided growth of graphene on the surface of MgO; right: MgO as spacers to separate graphene layers). (Image by MA yanwei)

The study entitled ‘Scalable Self-Propagating High-Temperature Synthesis of Graphene for Supercapacitors with Superior Power Density and Cyclic Stability’ has been published online in Advanced Materials.

Contact:

Prof. MA Yanwei

Institute of Electrical Engineering, Chinese Academy of Sciences

Beijing 100190, P. R. China

E-mail: ywma@mail.iee.ac.cn